3 Key Tips for Extending the Life of Your Printed Circuit Board

- Share

- Issue Time

- Aug 16,2022

Summary

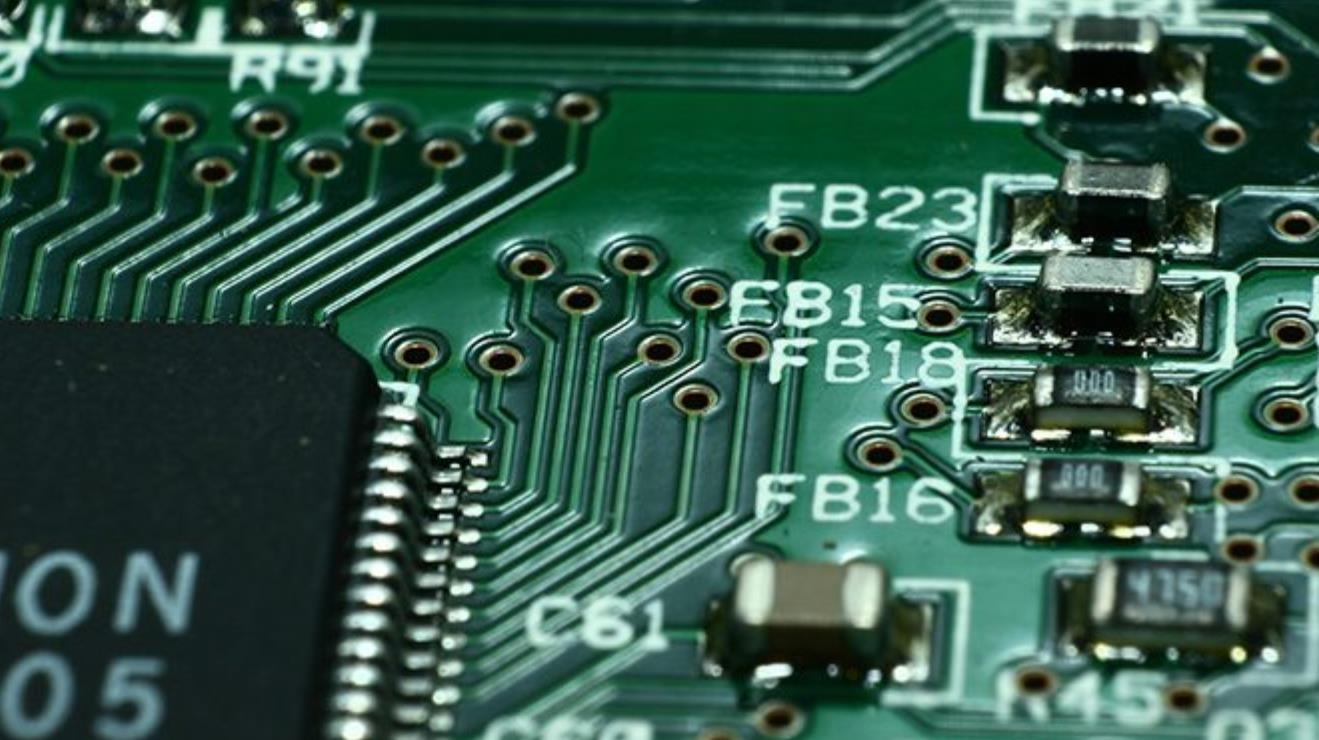

As you probably know by now, printed circuit boards don't last forever. Not even the very expensive ones in industrial equipment. But did you know you can extend the life of your circuit board?

As you probably know by now, printed circuit boards don't last forever. Not even the very expensive ones in industrial equipment. But did you know you can extend the life of your circuit board?

The number one reason a printed circuit board needs repair is component aging. There is nothing you can do about it. But what about the second biggest reason they end up repairing? That's damage from dirt, heat, moisture, and neglect/accidents. Now, this is under your control.

Here are 3 key tips for saving money with good board maintenance:

Clean in time

Clean the dust accumulated on the PCB every 3-6 months. You can also use special cleaning fluids designed for electronics. After removing all dust and grime, use a hair dryer to dry the board before reinstalling or using the equipment.

Active

Periodically inspect your PCB components for visible signs of damage (usually caused by overheating). Look for burn marks, solder joints, and breakage marks. Check whether the electrolytic capacitor is bulging or leaking. Anyone can do this as these are obvious problems and don't require test equipment.

Also, inspect connectors for common signs of corrosion, especially edge connectors. They can be cleaned gently with an eraser and a soft, lint-free/static-free cloth. Corrosion is a sign of excess moisture, so to avoid future damage, find the source of the moisture and remove it if possible.

If you are using thermal grease-coated equipment, you should check that the thermal grease is dry. If it gets too dry, wipe it down lightly, then apply new thermal grease to help dissipate heat - especially important as we know too much heat can cause damage.

Protect your PCBs with good storage and handling techniques

Store your electronics in a Moisture Barrier Bag (MVB). The thicker the better, so buy the best you can afford. Vacuum and heat seal the bag to remove as much air as possible.

Use a desiccant bag to absorb moisture and include a moisture/humidity card that can detect any moisture. This will let you know if the storage bag is damaged.

Keep the spare board at a consistent and cool temperature - between 60-70 degrees Fahrenheit

If you store many circuit boards or other electronics, invest in the best humidity-free environment you can afford. The best option is a dry atmosphere cabinet to maintain very low humidity (>5% RH).

Keep your electronics storage room away from dust, extreme temperatures and humidity, and excessive vibration. It's best to have a dedicated and secure storage room with strict access records for incoming and outgoing parts.

The above briefly introduces the maintenance method of PCB. If you want to buy or customize a PCB board, please contact us.

Singo is a professional custom PCB board manufacturer. Our company has been specialized in electronic PCB assembly. Mainly engaged in PCB assembly and OEM/ODM electronic manufacturing services since 2006. The products involve home appliances, digital products, industrial control, and medical equipment. After years of hard work, we have established long-term cooperative relations with some internationally renowned companies.