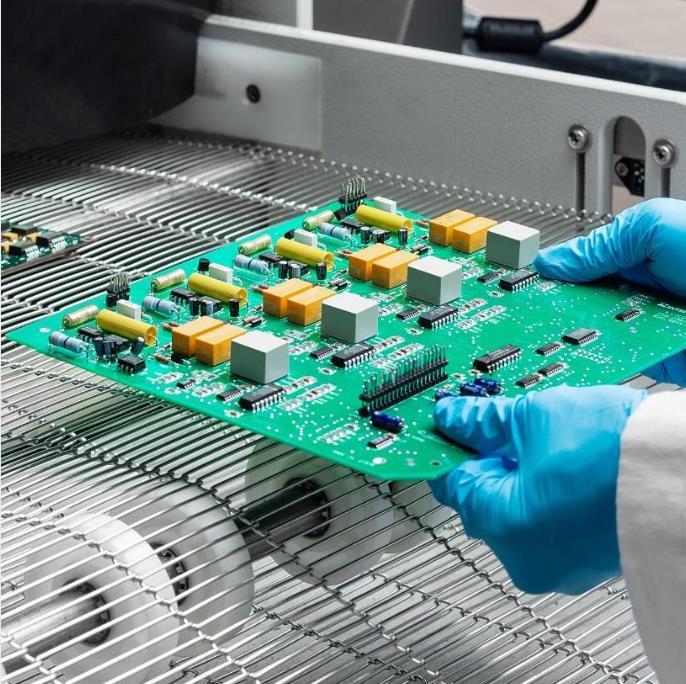

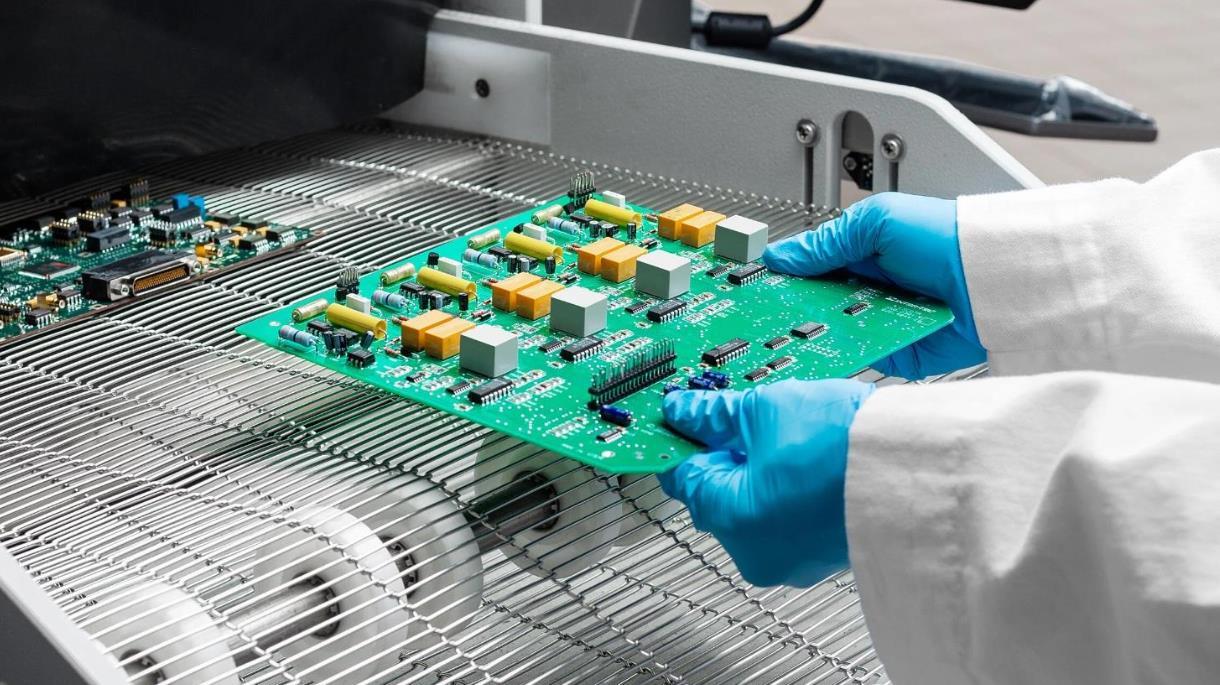

How to Clean PCBs?

- Share

- Issue Time

- Aug 29,2022

Summary

Cleaning printed circuit boards is a process as delicate as making them. To prevent damage to the PCB during cleaning, below we will discuss proven PCB cleaning options.

Printed circuit boards, especially those used in PDA devices (personal digital assistants, such as mobile phones), are often abused. In addition to collecting dust and dirt that seeps into phone cases, e-book readers, and similar handheld devices PCBs are known to be immersed in and splashed from liquids during everyday use. As a result, the service industry has emerged to provide cleaning and repair services for contaminated PCBs, rather than physical damage in PDAs and larger devices.

Cleaning printed circuit boards is a process as delicate as making them. If the wrong cleaning method is used, connections may be damaged, components may become loose, and materials may be damaged. To avoid these pitfalls, you need to choose the correct cleaning method just as carefully as you do when designing, specifying, and producing your circuit board.

What are these pitfalls and how do you avoid them?

Below we'll explore proven PCB cleaning options.

Different types of pollutants

There are various contaminants that can accumulate on PCBs. Solving problems with the right corresponding approach will be more effective and efficient, with fewer headaches.

Dry contaminants (dust, dirt)

One of the most common is the accumulation of dirt or dust in or around the PCB. Gently use a small, delicate brush, such as a horsehair paint brush, to remove dirt and dust without affecting the components. There are limits to where even the smallest brushes can reach, such as under components.

Compressed air can reach many areas but can damage important connections and should be used with extreme care.

A vacuum cleaner designed for electronics is also an option but doesn't get anywhere.

Wet contamination (dirt, wax oil, flux, soda)

The high-temperature operation can cause some wax-coated components to become magnets for dust and dirt, resulting in sticky grime that cannot be removed with a brush or vacuum. Or a product got a sticky soda bath that made a mess of the board. Either way, these substances should be dealt with before they build up and affect performance.

Most dirt can be removed with a cleaning agent such as isopropyl alcohol (IPA) and a cotton swab, a small brush, or a clean cotton cloth. Cleaning of PCBs with solvents such as IPA should only be done in a well-ventilated environment, preferably under a fume hood.

Demineralized water can be used as an alternative. Be sure to remove excess moisture and dry the board properly (a few hours in a low-temperature oven will effectively remove any residual moisture.)

In addition to IPA, there are many commercially available PCB cleaners, from acetone to chemicals used to clean electronics. Different cleaners can address specific types of contamination, such as flux or wax. Keep in mind that harsh cleaners can remove component markings or damage plastic or electrolytic capacitor sheaths or other special components (like humidity sensors), so make sure you're not using a cleaner that's too strong. If you can, test the cleaner on older components or connectors that you don't need to make sure it does more harm than good.

In conclusion

There are companies specializing in PCB cleaning. Please note that we do not provide PCB cleaning services! We are a high-end supplier of PCB manufacturing and assembly.

Depending on your needs -- such as a large number of boards, what needs to be cleaned, and how fragile the boards are -- you may be looking for outside resources to meet your cleaning needs.

If you're constantly having issues with boards that need cleaning, there may be some more important issues to check during the design or manufacturing process. Our consulting engineers can help you pinpoint problems and develop long-term solutions to better ensure PCBs remain clean and operating within tolerances.

Cleaning a PCB doesn't have to be a daunting task. Keeping the above tips and advice in mind will help ensure cleaning is done correctly. If you want to customize PCB board, welcome to contact us.

Singo is a professional custom PCB board manufacturer. The products involve home appliances, digital products, industrial control, and medical equipment. After years of hard work, we have established long-term cooperative relations with some internationally renowned companies. Some of our products are often required to operate in harsh environments where quality and reliability are paramount. With years of experience, we have won a good reputation among customers in the field of electronic production with reasonable prices, abundant resources, and on-time delivery.