PCB Colors - How To Choose The Color You Need

- Share

- Issue Time

- Sep 21,2022

Summary

For the past few years, green has been considered the standard PCB color. With the advent of technology and more innovations, different PCB colors are now also available. This guide will help you understand the basics of PCB board and solder mask colors.

For the past few years, green has been considered the standard PCB color. With the advent of technology and more innovations, different PCB colors are now also available.

A printed circuit board commonly referred to as a PCB, is the foundation of every chip circuit. The key important concept that forms the core of an electronic product is the PCB board.

People often forget to comment on this particular field. However, the basics of PCB color must be understood.

This guide will help you understand the basics of PCB board and solder mask colors.

1. PCB color

1.1 Definitions:

The color of the PCB determines the color of the solder oil or solder mask. It consists of lacquer impregnated with pigments known to protect traces of bare copper. Made of glass-epoxy, the PCB's finish color represents the solder mask. One of the main applications of solder masks is to prevent short circuits on circuit boards.

1.2. PCB color type:

PCB boards are available in different types of colors. The standard color for printed circuit boards is a green solder mask. However, with the advent of many innovations and technological advancements, the color of PCBs is now changing. In recent years, the use of other colors to replace green PCBs is increasing, driven by most assemblers. Here are some reasons to choose a color PCB other than green:

• Use different colored PCBs to clearly display version changes for users to understand.

• Using a color other than green can produce brightness or shrinkage. You need to be aware that the transmission properties, absorbance, and light reflectivity of the assembled device are important.

• Using different colors will help prevent various errors that can occur in mixed assemblies. The choice of contrasting color types also has the advantage of identifying lead-free meetings.

Color types used to make PCBs include white, blue, black, yellow, red, etc. The color of the PCB is often referred to as the PCB color code. Different modern PCB types have specific colors. For example, PC motherboards are still made of green epoxy.

The color of the solder mask will not have any effect on the performance of the PCB. However, with the use of different PCB colors, the board resolution will vary. For example, green PCB resolution uses red and blue to match, for example, with yellow and black, the resolution is significantly reduced. It is important to note that solder mask layers with clear transparency tend to have high resolution.

2. PCB solder mask color

If you are going to choose a printed board, there are some parameters to consider. One of them is choosing the color of the PCB solder mask. While green is the most traditional color, other colors such as yellow, white, and black are also available at no extra cost. Since the PCB solder mask is available in many colors, the question is which color to choose. Are there any advantages or disadvantages to choosing any color other than green? The little guide given below will help you choose different solder mask colors other than the standard green:

♦ Red:

Red solder mask colors tend to be bold and professional. The contrast between planes, spaces, and trajectories is excellent.

Contrary to green PCBs, the contrast is lower. Any magnification is used to inspect circuit board traces for defects. It's important to note that screen printing is known to work well against red backgrounds because it removes flux residues. While red looks appealing, striking and bold, green is still considered the best.

♦ Blue:

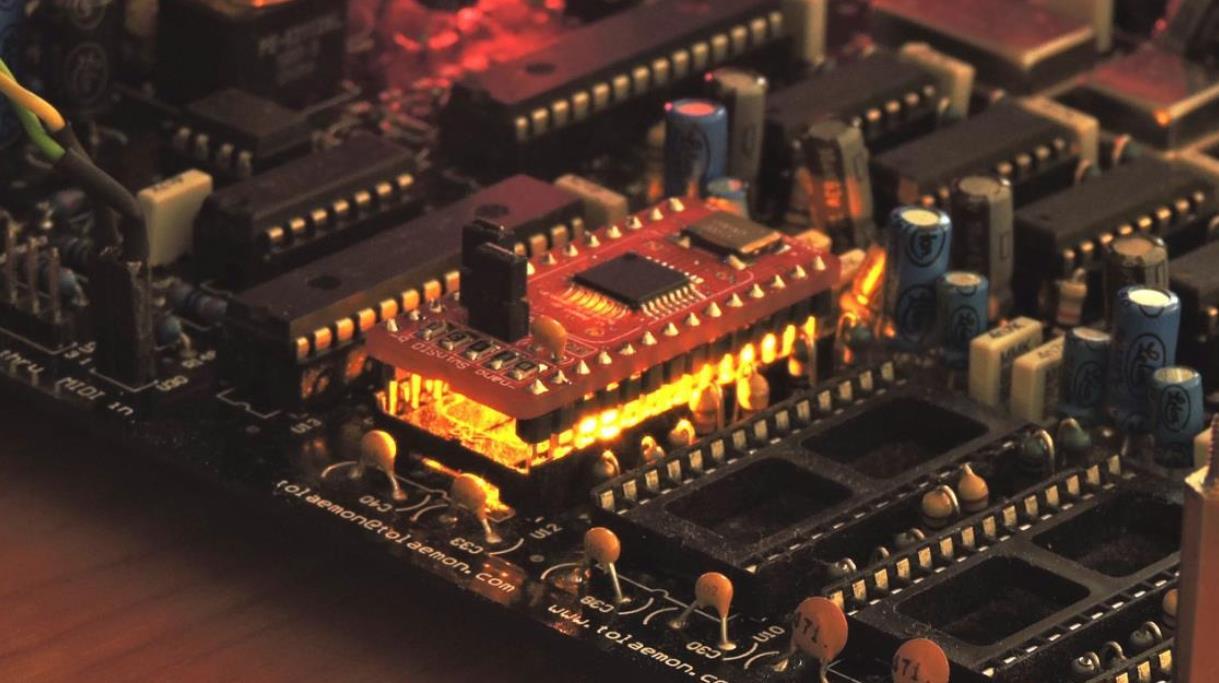

The PCB color blue for the solder mask is similar to the same Arduino blue. The contrast between white space, planes, and traces is shallow compared to red and green PCBs. In the blue solder mask color, magnification is considered necessary and mandatory for the inspection of manufacturing defects.

However, it is important to note that the contrast between the solder mask and the silkscreen is relatively high, which is a plus point for using blue. So if you're using a board with a label - heavy, the correct choice, in this case, is probably blue.

Keep in mind that if you want to match the solder mask color to your Arduino, and you don't care about showing the traces off the board, blue seems like a good choice.

♦ Black:

Black PCB colors are difficult to handle. The contrast between empty spaces, planes, and traces is lower than other solder mask colors, but not present. Examining this plate requires very powerful magnification. Checking it is nothing but a nightmare as it requires an oblique angle to cast shadows to find traces.

Another problem with black PCB color is its heat absorption during reflow. In terms of cleanliness, the black solder mask takes effort as flux stains tend to be harder on the board and eventually require steps to be removed.

One of the advantages of a black solder mask is that it contrasts well with screen printing. The distinction between silkscreen and pads is pretty good. You don't need any lighting or optics to see a visible difference. Currently, only glossy black is available. The matte black solder mask color still needs to be prototyped.

♦ White:

If you thought black solder mask was the hardest to deal with, you haven't seen white. Experiments have shown that there is no benefit to a white solder mask. Compared to black, white PCB colors have even the lowest contrast. Even tilting it into the light doesn't help the appearance of its marks when inspected. It's so hard to clean a white printed circuit board because it's hard to see the tips. However, the white solder mask has the same silkscreen contrast as the black, which means they work just fine. Considering other parameters, we do not recommend a white solder mask.

♦ Yellow:

There are surprising reasons why designers and engineers don't choose yellow PCBs. The contrast between empty spaces, traces, and planes in the yellow solder mask is too high. It's almost the same as green. So if you have some great wiring and your printed circuit board is a hard work of art, a dark and coppery yellow solder mask is the right choice for you.

Since the white silkscreen does not contrast well, you can use a black silkscreen and a yellow solder mask. As can be seen, it will create excellent results for your designs and work. Also, you can see that the yellow solder mask does not cause any cleaning issues. Yellow should be considered along with green and red, depending on its excellent performance parameters.

So, it's all about the different solder mask colors. Following the guidelines discussed above will make it easier for you to choose the right color for your next project.

Why is the circuit board green?

Considering that there are several different PCB colors to choose from, why is green always considered the standard color?

Green PCB board can relieve visual fatigue. Workers prefer to use them as greens do not require enhanced inspections. The less scrutiny of green printed circuit boards, the less tiring the job will be. Additionally, human eye sensors are reportedly sensitive to green. As mentioned earlier, green PCB color contrast is higher and is suitable for quickly identifying circuit board traces and residues.

It can also be seen that the green solder mask outperforms the other solder mask colors. Green solder mask has different excellent properties compared to other solder mask colors. This color works well with solder masks and plays a role in the manufacture of integrated circuits.

As mentioned earlier, green printed circuit boards are standard circuit boards and are mass-produced; they can be the first choice. If one wishes to make other choices, it will take more time, money, and effort. This is not the case with green.

3. Conclusion

Take care when choosing the color of your PCB. Printed circuit boards are the foundation of every electronics project. If it goes wrong, the whole system will be disturbed. You need to choose PCB colors carefully, as cost savings through improved circuit efficiency are critical. If you want to customize or buy a PCB board, welcome to contact us.

Singo is a professional custom PCB board manufacturer. Our company mainly deals in PCB assembly and OEM/ODM electronic manufacturing services. The products involve home appliances, digital products, industrial control, medical equipment, etc. After years of hard work, we have established long-term cooperative relationships with some internationally renowned companies. Some of our products are often required to operate in harsh environments where quality and reliability are paramount. With years of experience, we have won a good reputation from customers in the field of electronic production with reasonable prices, abundant resources, and punctual delivery.