Why Are Multi-layer PCBs Commonly Used?

- Share

- Issue Time

- Oct 10,2022

Summary

Due to the versatility of multilayer PCBs, it is widely used in many devices. There are many benefits to using these printed circuit boards. The following is a detailed introduction to the benefits of using multi-layer PCB boards.

Single-layer and multi-layer printed circuit boards are commonly used in a variety of applications. Single-layer PCBs are used for simpler devices with basic functions, while multi-layer PCBs can be used for more complex devices with more functions. PCB manufacturers have seen an increase in demand for multi-layer boards as various industries and sectors require smaller, complex devices.

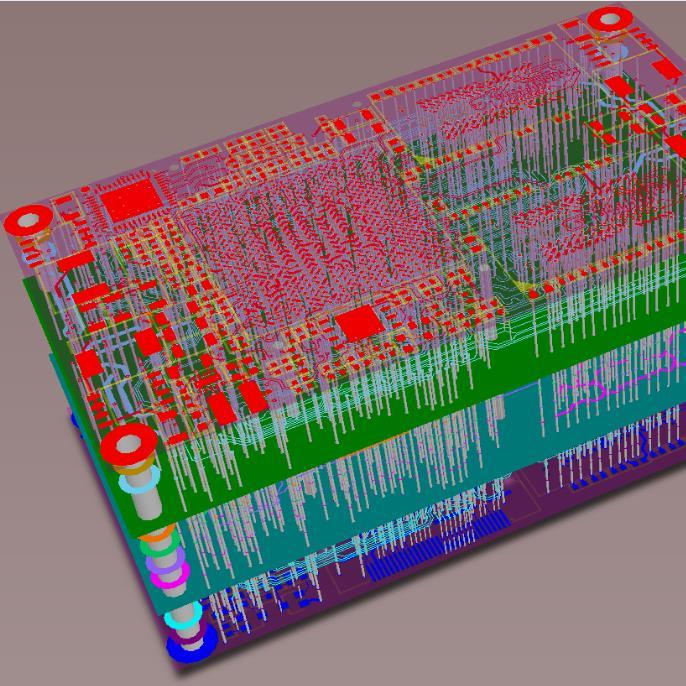

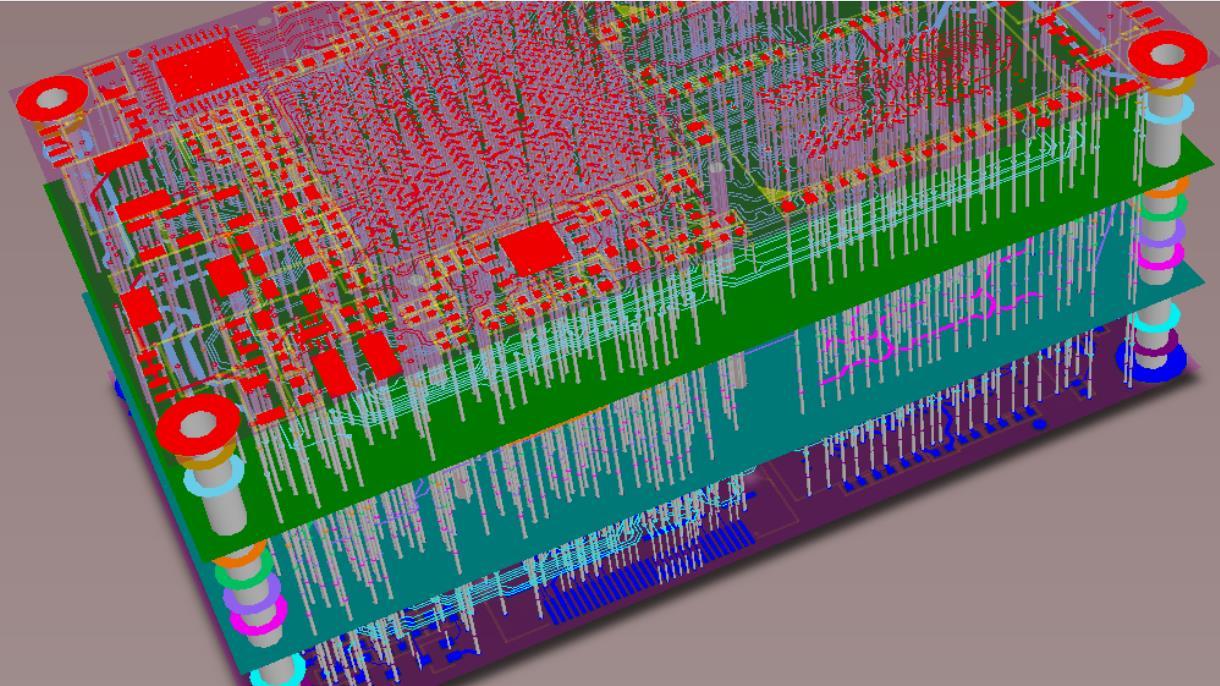

Multilayer PCBs are commonly used in various professional electronic products such as computers, cell phones, heart monitors, and more. Multilayer PCB fabrication involves laminating more than two conductive layers together and can have varying numbers of layers, depending on application requirements. Having more layers inside the board allows more circuits and routing for more complex applications. For example, cell phone-printed circuit boards can have up to 12 layers because they are very complex devices.

Due to the versatility of multilayer PCBs, it is widely used in many devices. There are many benefits to using these printed circuit boards.

Benefits of multilayer PCBs

Technically and design-wise, multilayer PCBs offer many advantages. Here are some key benefits of these boards:

Increase functionality and capability - By laminating multiple layers together, you can effectively increase the functionality and capability of your printed circuit board. With more layers, you can fit more circuits and wiring into the board.

Available in rigid or flexible - These multilayer printed circuit boards are available in rigid or flexible configurations, depending on your requirements. However, the more layers you add to the board, the less flexible it becomes.

Usually smaller size - This saves space when you group layers together. Multiple layers allow you to get high capacity with a smaller footprint, which can be beneficial for smaller devices.

Lightweight - Due to the layered configuration of these printed circuit boards, it eliminates the need for separate PCB connectors. This simplifies the manufacturing process, saving not only space but also the overall weight of the circuit board.

Overall, multilayer boards are generally of better quality than regular PCBs because more design, planning, and investment are put into the development of these types of boards. While it may cost more, it more than makes up for the price in terms of features and performance. These boards are usually designed as a unit, which makes it easier to mount the board to the final product. If you want to customize or buy a PCB board, welcome to contact us.

Singo is a professional custom PCB board manufacturer, whose products involve home appliances, digital products, industrial control, medical equipment, etc. After years of hard work, we have established long-term cooperative relationships with some internationally renowned companies. Some of our products are often required to operate in harsh environments where quality and reliability are paramount. With years of experience, we have won a good reputation from customers in the field of electronic production with reasonable prices, abundant resources and punctual delivery.