What Makes Flexible PCB Boards the Best Choice for Satellite Applications?

- Share

- Issue Time

- Dec 1,2022

Summary

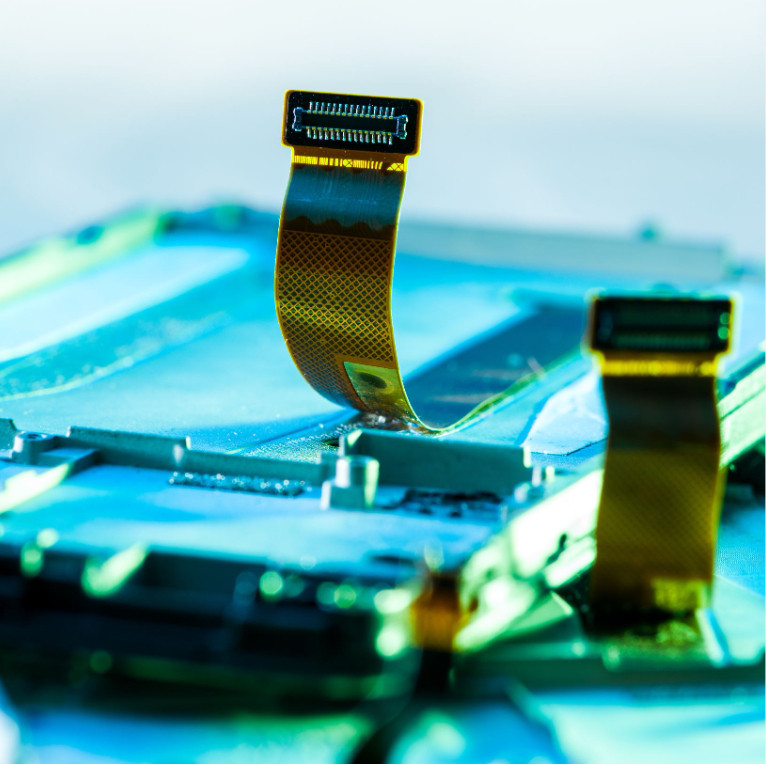

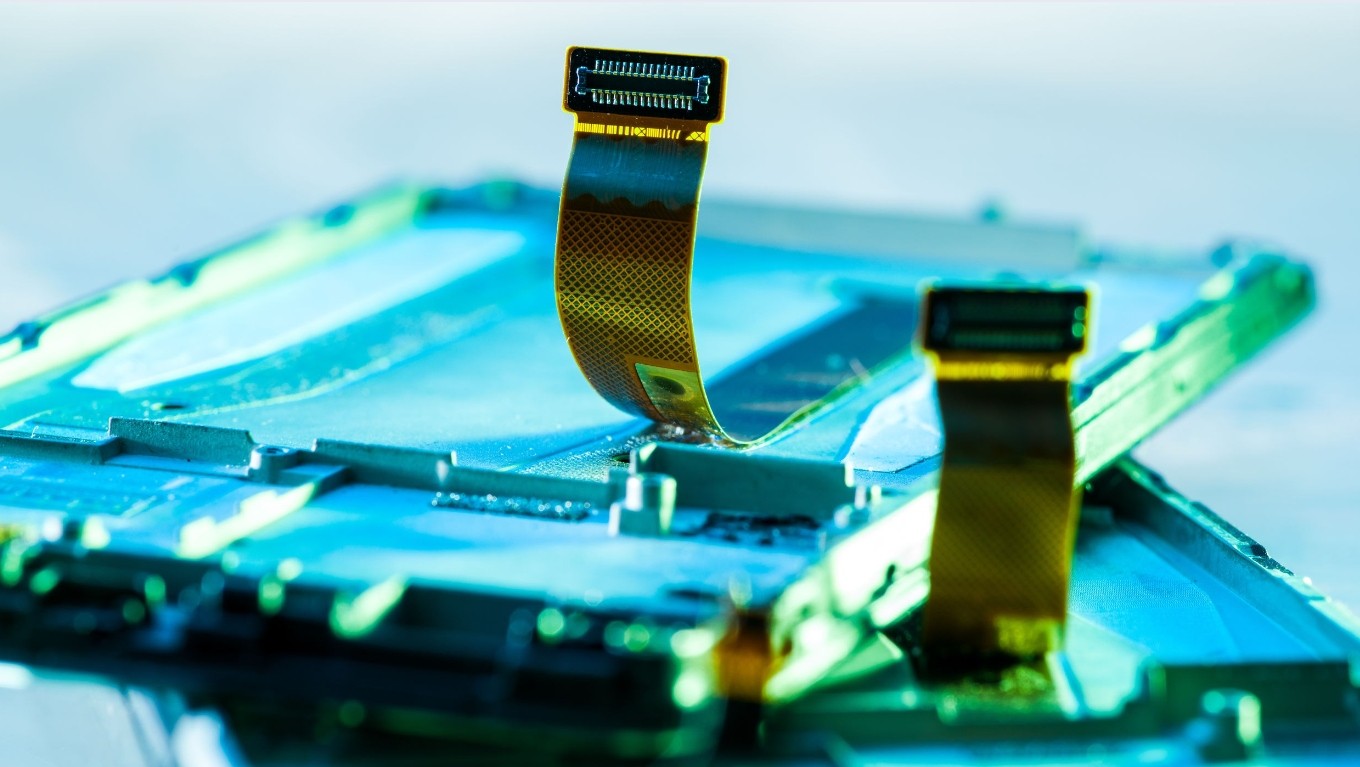

From reduced weight to increased reliability, flex PCBs offer many advantages for satellite applications. Below we introduce the application of flexible PCB boards in satellites in detail.

When it comes to satellite applications, the use of flex PCB boards is only going to grow! Not without reason! There are many benefits that are driving industry players to adopt flexible PCBs. From reduced weight to increased reliability, flexible PCBs offer many advantages. Before we get into the details of some of these advantages, let's understand how satellites work:

How Do Satellites Work and What Are Their Use Cases?

There are 3 main circuits in a satellite system, namely:

Satellite

Recipient

Transmitter

The communication between the satellite and the transmitter is called the uplink, while the communication between the satellite and the receiver is called the downlink.

Use cases for satellites include:

Disaster risk management

Weather forecast

Remote sensing

Geolocation

Navigation

Telecommunications

Emergency response monitoring

Satellites can be further divided into 3 types: fixed, mobile and broadcast, depending on the services they provide. Fixed satellite services use fixed receiving stations. These are mostly used on cable TV and Internet sites. Mobile satellite services also deal with mobile systems that communicate with fleet vehicles. Broadcast satellite services broadcast television and radio signals.

Given the functions performed by satellites, let us now look at the need for flexible PCBs in satellite applications.

Advantages of Using Flexible PCB Boards in Satellite Applications

Reliability

Satellites represent mission-critical operations, and failure can be extremely costly. Therefore, the PCB used must be very reliable. Since flexible PCBs are able to withstand higher stresses than rigid PCBs, they are suitable for satellites that are subjected to harsh environmental conditions. Additionally, Flex PCB eliminates the use of connectors, which often cause interconnects to fail. So you can have peace of mind when using flex PCBs in satellites.

Adaptability

One of the big advantages that flex PCBs offer is that they are extremely adaptable, and the pads themselves fit into regular shapes. Flex PCBs can be mounted to the different surfaces they are mounted on. However, this is not possible with rigid PCBs that cannot be used in complex shapes.

Their flexibility also comes in handy when you need scalable parts. With flex circuits, you can use consumable devices without worrying about wear and tear.

Light

With thinner layers of copper and insulation, flex circuits are lightweight and can also fit into tighter spaces with tight bend radii.

While flex circuits are made from a variety of materials, Kapton is particularly popular because of its lightweight. In addition, it is also known for its mechanical properties and vibration resistance.

Therefore, while flex PCBs are well suited for use in satellites, PCB designers must consider the following conditions when designing satellite PCBs:

Operating Temperature

It is important that the materials selected for PCBs deployed in satellites are suitable for harsh operating conditions. In fact, the material chosen should be able to withstand high temperatures of 120 degrees Celsius or more.

Outgassing

When the PCB is working in a high-voltage environment, the gas trapped in the PCB will be released. Released gas can condense on other parts and cause operational problems. Therefore, it is important to choose materials with good heat resistance so that outgassing is controlled.

Orbital Collision

For satellites, orbital collisions could be a reality. Therefore, the PCB should be able to withstand such impacts. To ensure this, the bending capacity of the PCB should be high.

PCB Standards for Satellites

Because of these unique issues, there are specific standards for space applications. Common standards include:

AS9100

Created by the International Aerospace Quality Organization, this standard is useful for creating products for the aerospace industry. AS9100D is the latest standard that the aerospace industry needs to comply with.

Additional standards for aerospace and military-grade PCB assemblies include:

MIL-PRF-50884

MIL-PRF-31032

MIL-PRF-55110

Summarize

Rigid-flex and full-flex PCBs offer several advantages over traditional PCBs. Their innovative design, reduced weight and more make them ideal. Not only does it help minimize the size of the spacecraft, but it also improves reliability.

The above briefly introduces the reasons why flexible PCB boards become the best choice for satellite applications. If you want to order PCB boards, please contact us.

Singo is a professional custom PCB board manufacturer. The products involve home appliances, digital products, industrial controls, medical equipment, etc. After years of hard work, our manufacturing facilities include dust-free workshops and advanced high-speed SMT lines (Yamaha), fully automatic printing machines, lead-free wave soldering and fully automatic assembly lines. Our placement accuracy on IC parts can reach ±0.03mm. This means we can handle almost all types of ICs such as SO, SOP, SOJ, TSOP, TSSOP, QFP, GA and U-BGA.