What is the Difference Between PCBA and PCB?

- Share

- Issue Time

- Mar 1,2023

Summary

Both PCB and PCBA are important terms in the electronics industry. In this guide, we'll take a closer look at the definition of PCB, the definition of PCBA, and the differences between these two terms.

Both printed circuit board and printed circuit board assembly are important terms in the electronics industry. Some people use them interchangeably, but they are actually two very different things.

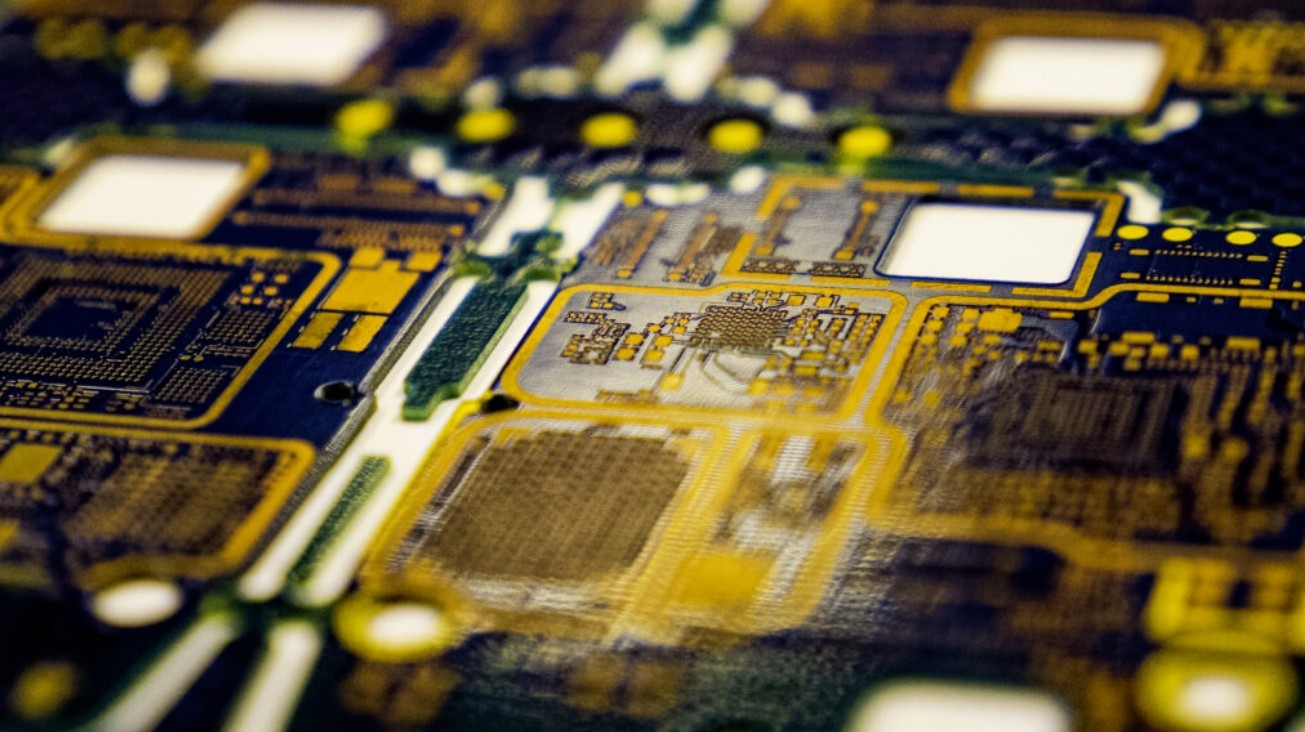

The main difference between the two terms is that PCB refers to a blank circuit board, while PCBA refers to a circuit board that contains all the necessary electronic components required by the board. A PCB is not yet functional because it does not have the required components, whereas a PCBA is a fully functional board. PCB and PCBA are two different parts of the same process - the PCBA builds on top of an existing PCB.

In this guide, we'll take a closer look at the definition of PCB, the definition of PCBA, and the differences between these two terms.

What is a Printed Circuit Board?

PCBs are the foundation of modern electronic devices. They mechanically support and electrically connect electronic components. The board itself is made of laminated materials such as fiberglass or composite epoxy and contains conductive pathways that connect the different parts of the board. These paths are printed or etched on the board according to the predetermined PCB design.

Types of PCBs

The main types of PCBs include:

- Single-layer PCB is the simplest type of PCB, coated with a single layer of conductive material and a layer of solder mask. The components of the PCB are marked with a silkscreen.

- Double-layer PCBs have a layer of conductive material on the top and bottom of the board, which allows them greater flexibility and smaller size than single-layer PCBs.

- Multilayer PCBs have more than two conductive layers for more complex applications.

Other common types of PCBs include flex PCBs, rigid PCBs, and rigid-flex PCBs.

Materials Used

The substrate material for PCBs is usually fiberglass, composite epoxy, or other laminated materials. The conductive material on one or both sides of the board is usually copper. Printed circuits that are plated or etched onto substrates depending on the design are also made of copper. The circuits are tin-lead coated to prevent oxidation. The outer edges of the PCB have contact fingers and are also coated with tin-lead and other materials such as nickel and gold to improve conductivity.

Application

PCBs are widely used in electronic equipment, including consumer electronics, heavy machinery, robotics, vehicle components, and medical equipment. Examples include:

Computer

Mobile phone

TV

Radio

Printer

Calculator

Home appliances

Lighting system

Medical imaging system

Pacemakers

Engine management system

Industrial control

Telecommunication towers

Data storage devices

Satellite systems

What is the Definition of PCBA?

A PCB refers to a blank board, while a PCBA is a complete PCB assembly that contains all the electronic components needed to make the board function as required. PCBA can also refer to the process of assembling a circuit board with the necessary components.

There are two main methods of PCB assembly that a PCBA company may use:

1. Surface Mount Technology

Surface Mount Technology (SMT) is an assembly process that involves mounting electronic components to the surface of a PCB. It is highly automated and flexible and allows for higher connection densities. It enables manufacturers to pack complex circuits into small components.

The four basic steps of PCBA SMT are:

- Preparing the PCB: First, the assembler places solder paste where it is needed on the board.

- Component Placement: Next, the assembler places the components on the board, usually using a pick and place machine.

- Reflow Soldering: The assembler then heats the board in a reflow oven until the solder paste reaches the temperature needed to form a solder joint.

- Inspection: Assemblers conduct inspections throughout the SMT process, including before connecting components and before and after reflow soldering.

2. Through Hole Technology

Through-hole technology is an assembly process that involves drilling holes in a PCB through which electronic components called leads can be attached. It is an older technology than SMT, but creates a stronger connection between the board and the components, resulting in a more durable and reliable assembly.

Through-hole assembly can be fully automatic or semi-automatic. The steps of the PCBA via process include:

- Drilling: The first step in the through-hole process is to drill holes in the board. These holes must be sized to accommodate the component leads.

- Place the Leads: Next, the assembler places the leads into the holes.

- Welding: The next step in the process is welding. This step ensures that the components are held securely in place.

- Inspection: Throughout the process, components are inspected to ensure that the PCBA will function as intended.

How are PCBA and PCB Related to Each Other?

PCB and PCBA are the results of two different steps of the same overall process. A PCB is a blank circuit board without any electronic components connected to it, whereas a PCBA is a complete assembly containing all the components needed for a circuit board to function as required for the desired application. The PCB is not yet functional, while the PCBA is ready for use in electronics.

Because of the various components and processes involved in PCB assembly, manufacturing a blank board is simpler than producing a complete PCBA. The cost of producing a PCBA is also higher than a blank PCB. However, both steps are necessary to create a complete board. A PCBA cannot be created without a PCB. PCB fabrication is the first step in the process, and PCBA fabrication builds on that first step.

Another difference lies in the way PCBs and PCBAs are packaged. PCBs are usually vacuum-packed, while PCBAs require compartment or anti-static packaging.

As a professional custom PCB manufacturer, SINGO provides professional PCB assembly services, including board level and full box assembly, SMT and through-hole technology, and everything from fully automatic processes to precise hand assembly. Mainly engaged in PCB assembly and OEM/ODM electronic manufacturing services since 2006. Our products involve home appliances, digital products, industrial controls and medical equipment. After years of hard work, we have established long-term cooperative relationships with some well-known international companies. If you want to order PCB, welcome to contact us.