All About Transparent PCBs

- Share

- Issue Time

- Apr 13,2023

Summary

Various LED and LCD devices use transparent PCBs due to their optical properties. However, the latest use of transparent PCBs is in 5G networks, which may well change the communication scene forever.

Recently clear glass technology is revolutionizing the printed circuit board or PCB industry. Various LED and LCD devices use transparent PCBs due to their optical properties. However, the latest use of transparent PCBs is in 5G networks, which may well change the communication scene forever.

Transparent PCB Substrate

Currently, the industry uses two main types of transparent PCB substrates – glass and ceramic. Transparent substrates based on ceramic materials have a higher thermal conductivity than transparent substrates made of glass. However, glass substrates provide higher light transmittance. The transmittance of ceramic transparent substrates is about 75-80%, while the transmittance of glass transparent substrates is about 99.5-99.99%.

Transparent Glass PCB Substrate

Glass usually comes from a mixture of sand, ash, limestone, and soda. These four materials are found everywhere in nature, so they are environmentally friendly and recyclable. The most common glass material is tempered glass. This is a reprocessed and prestressed glass with high durability. In addition, tempered glass has a high ability to absorb shocks and shocks.

Sapphire glass is the strongest and hardest of all glass variants. High-end electronic devices use sapphire glass because of its high dielectric and thermal properties. This type of glass is even useful in devices used in satellites and space.

Printed circuit boards made of clear glass transmit light in almost all directions. Therefore, light can be seen through the transparent PCB from almost all sides.

Advantages of Glass PCB Substrate

Glass PCB substrates offer many advantages:

Highly wear-resistant

High heat resistance

Highly resistant to deformation

Highly transparent

Extremely flat surface

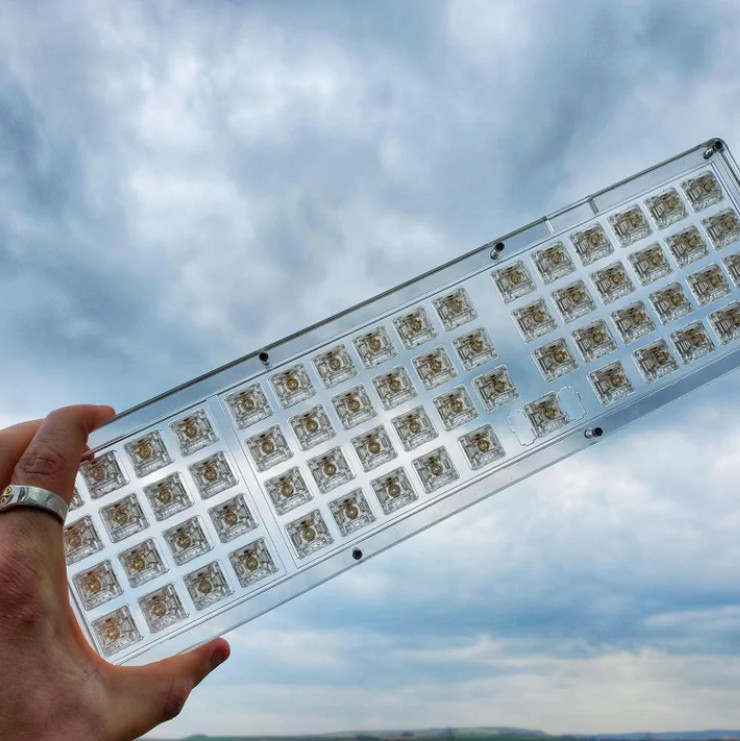

While the glass PCB substrate is transparent, the copper traces on the PCB are not. Therefore, the copper traces on the PCB can be seen through the glass. However, some manufacturers are using new techniques to make the copper traces also as transparent as the glass substrate.

Due to the characteristics of glass substrates, glass PCBs subjected to high temperatures for a long time exhibit very low deformation rates. This is one of the most desirable properties of PCB glass substrates. Glass can withstand temperatures of around 1000℃, and transparent PCBs are easy to manufacture due to the abundance of raw materials. This also makes glass PCBs less expensive than ceramic PCBs.

Transparent Flexible PCB

Using PET film, PCB manufacturers are able to create transparent flexible PCBs. They make them in many colors like clear, light blue, white, light green, and more. Transparent PET material allows for making transparent flexible PCBs different from regular flexible PCBs.

Fully Transparent Printed Circuit Board

Special innovative technology makes the conductive traces also completely transparent. The manufacturer sandwiches the circuit with conductive traces between two layers of PET film to protect it and make it completely invisible from the outside.

Advantages of Transparent Flexible Pcb

Offers many optical properties

Can be folded, bent, twisted, and moved arbitrarily in three-dimensional space

Very dimensionally stable

Compared to a conventional rigid PCB of the same size, the weight of the PCB is reduced by about 90%.

Contributes to a reduction in size, weight, and miniaturization of products.

Application of Transparent Flexible PCB

Flexible transparent PCBs have many uses. Applications include medical equipment, electronic calculators, cell phones, cameras, ABS systems, instrument panels, automatic control systems, and PCB requirements in confined spaces. Applications of transparent flexible PCBs also include smart contact lenses, electronic skin, and flexible transparent electronics.

Transparent Ceramic Circuit Board

Manufacturers create transparent ceramic circuit boards using a variety of materials such as magnesia spinel, arylene, yttrium oxide, magnesium oxide, and aluminum oxide or aluminum oxide. For example, they use fine aluminum oxide powder at the nanoscale, which is added to the resin-water liquid at a concentration of 5 – 10%. This helps increase the resin hardness from 6H to 8H. Some manufacturers use oil-based alumina fluids, while others use water-based alumina fluids for clear ceramic circuit boards.

Most transparent ceramic PCBs use a transparent substrate with a glass-based solder mask. However, conductors are not transparent. Transparent substrates are approximately 75 – 85% transparent. A glass solder mask covering the traces helps maintain the transparency of the substrate.

Advantages of Transparent Ceramic Circuit Boards

Offers many optical properties

High-temperature resistance. For example, 2000+℃ is normal. The glass transition temperature of thorium oxide and yttrium oxide circuit boards can reach 3100℃.

High thermal conductivity exceeding 24 – 31.4 W/mK.

Very low and very stable coefficient of thermal expansion

High electrical insulation

Very low water absorption

Application of Transparent Ceramic Circuit Board

Applications of transparent ceramic circuit boards include optical sensors, high-power LEDs, high-pressure sodium vapor lamps, missiles, infrared windows for aircraft, etc.

In Conclusion

Several revolutionary changes are taking place in the PCB industry. Manufacturers are using many innovative technologies to meet the needs and requirements of different electronic devices. One of these innovative technologies is the development of transparent PCBs. With the advent of 5G, LCDs, and LEDs, we will see more uses for transparent PCBs. Singo is a full-service custom PCB assembly manufacturer, so our team is available throughout the conceptualization phase and through successful product launches. Our top priority is to deliver high standards of work and fast turnaround times in everything we do for you. With advanced equipment and skilled engineers, we can provide a variety of electronic manufacturing services, and can complete short-term production of up to 10,000 pieces at a time. If you want to customize the PCB board, welcome to contact us.